- Formentechnik Bayreuth

- +49 921 1508304 – 0

- info@formentechnik-bayreuth.de

In good shape – Molding technology

Automotive, communications, electrical and medical technology

Products

Development and production

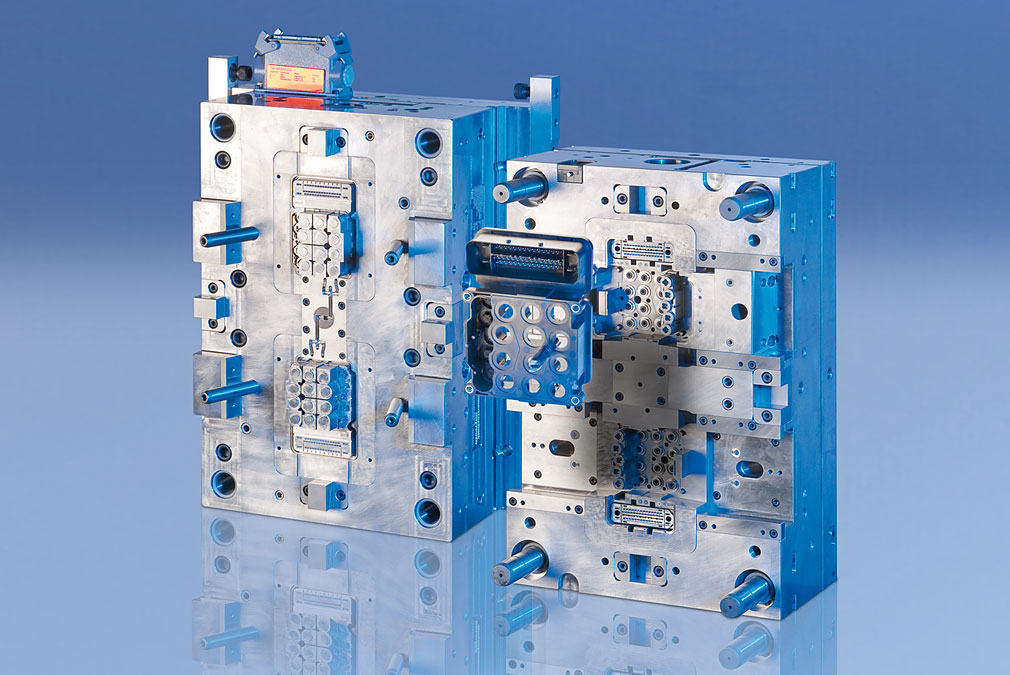

We are a system supplier for the highest difficulty levels in the range up to 3,000 kilograms tool weight in 1- and 2‑component technology for the automotive, communications, electrical and medical technology industries. Our incentive is to produce 32-cavity and 64-cavity series molds whilst retaining particularly high uniformity amongst the large number of cavities, or to form the 250-gram housing frame with as little distortion as possible through innovative mold cooling. We are equally committed to mastering the back-injection of aluminum, carbon and wood panels or the insertion of boards for overmolding in tools with sharp-edged embeddings, without embossing when closing the tool.

Formentechnik Bayreuth GmbH is a specialist in the development and manufacture of injection molds. We offer our customers the greatest possible benefit from the molds manufactured at our company. Single and multi-cavity tools, injection and overmolding tools with complex inserts, tools for injection-molded seals, valves and pistons, precision medical technology parts, tools for high-temperature materials, connectors and cable overmolding. Injection weights from 0.02 grams to 570 grams can be processed in the individually manufactured tool.