- Formentechnik Bayreuth

- +49 921 1508304 – 0

- info@formentechnik-bayreuth.de

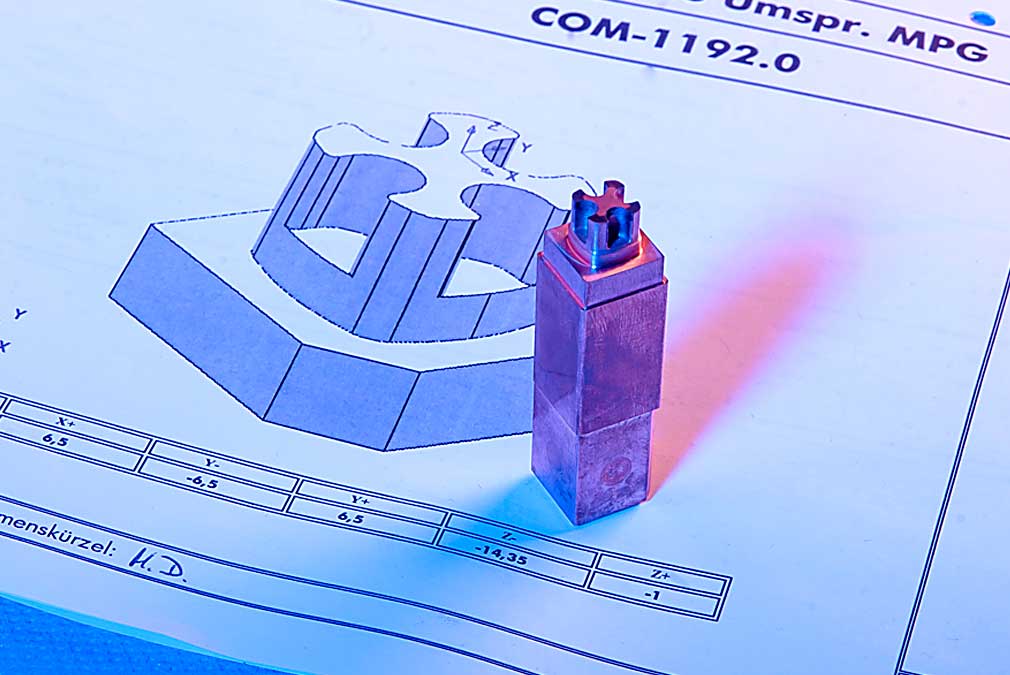

… you need to get up early! That’s our creed at kick-off meetings for customer projects. Parallel to the tool design, calculations and simulations are already being prepared, hotrunners requested and special tool technologies checked. Production in the departments begins following a final design meeting. The ordering of standard and special parts takes place in parallel with the program creation for the planned machine tools and the machining cell.

During the production of the individual parts, the first components are already joined and prepared for final assembly. The finished tool is then immediately made available for your series system for the production of the first parts. Article measurement and final tool corrections are then carried out to bring the tool into ‘top form’.